How We Made the Mark Awards

The Mark Awards ceremony presented a chance for us to honor those professionals who exhibit pride in everything they do, from selling Exmark mowers to running Exmark red when mowing lawns. Here at Exmark, we have pride too. The Mark Awards gave a chance for some of our employees to show it when they created the actual trophies at our Beatrice plant.

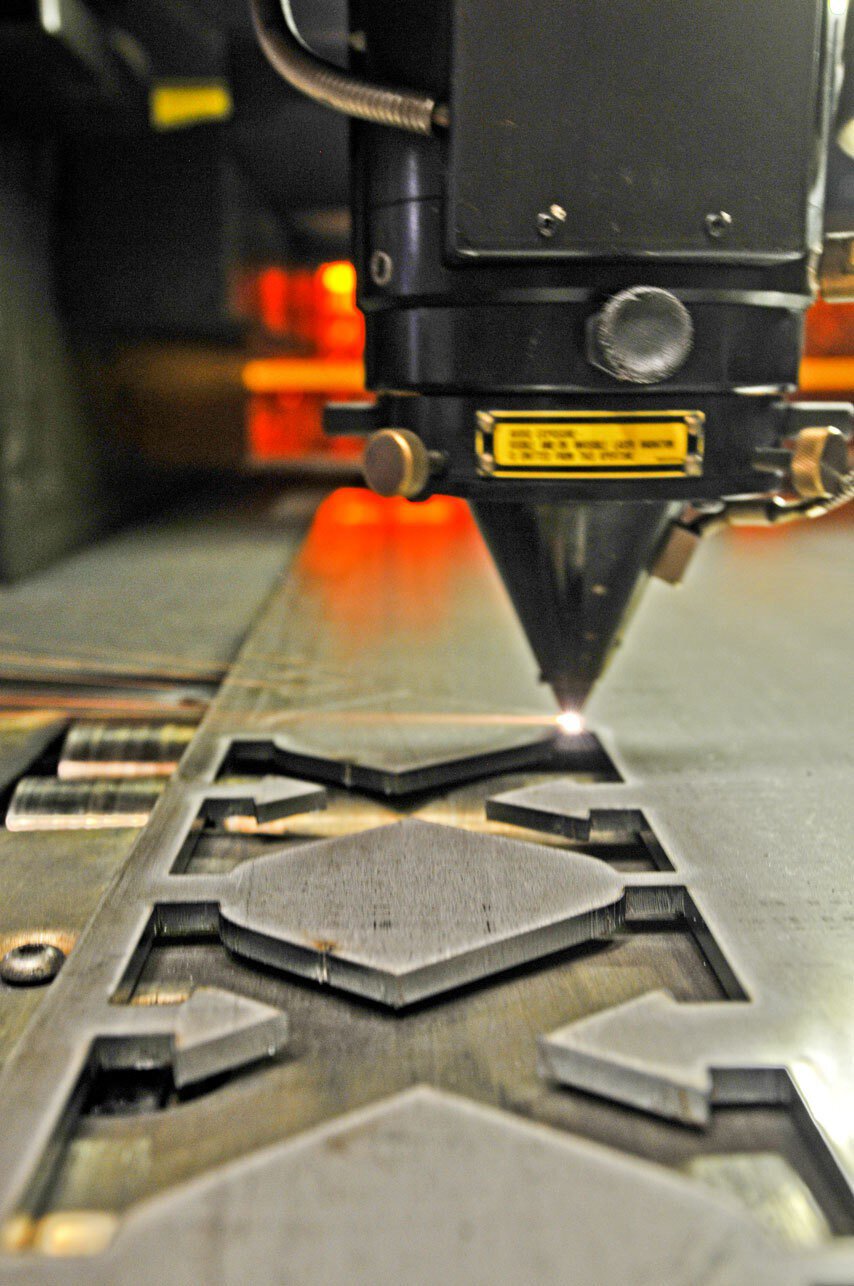

The trophies were made in-house using some of the most advanced technology in our manufacturing plant. Brian York, an Engineering Process Improvement Specialist who’s been with Exmark for over nine years, explained that the trophies were designed using CAD (Computer-Aided Design) software. After design, a number of different machines were used to produce the various parts of the award:

- The base was created using our 3D prototype printer through a process called “rapid prototyping.” It’s the same process used to create prototype parts in which we test form, fit and function on the mowers.

- The red circle and “X” were manufactured using our in-house laser cutter.

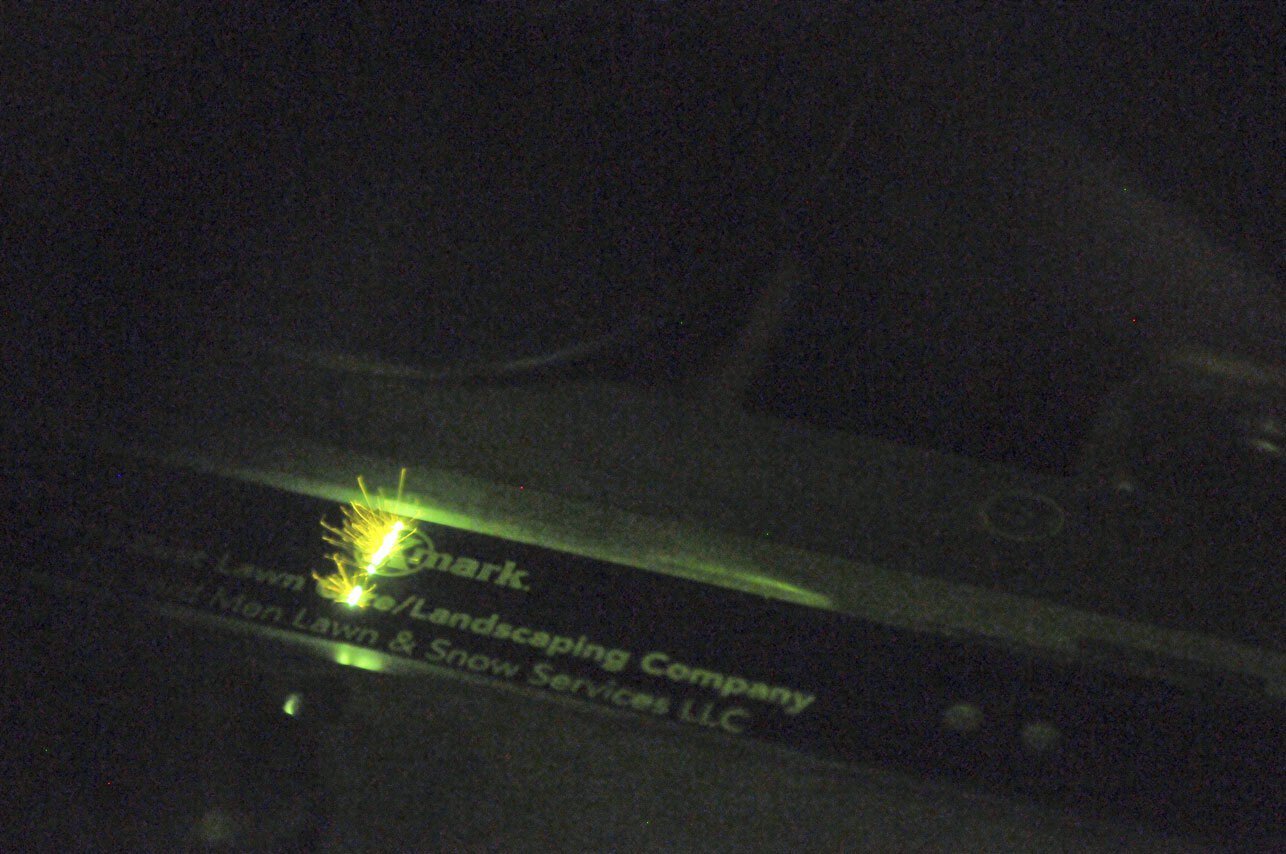

- The nameplate printer etched the names of the winners.

- The white decal on the “X” was cut using our prototype vinyl cutter.

How do you think the Mark Awards trophies turned out? Want to know more on how the awards were made? Let us know with question or comment below.